Locking rings and washers

Machine components including DIN 705 locking rings, thick washers, and threaded ring nuts. These are essential during assembly to position bearings or other components, or to serve as a mechanical stop.

- Fully turned steel construction;

- High-quality surface finish with deburred edges;

- Burnished or galvanized surface treatments;

- Cost-effective and available from stock.

- Available in stainless steel or with Niploy treatment;

- Customization based on customer drawings.

- Automated machinery.

- Conveyor belts;

- Textile machinery;

- Packaging machinery;

- Film stretching machines.

- Creation of a perfectly orthogonal contact surface;

- Ideal for bearing assembly and fixing rod ends;

- Compatible with any type of screw;

- Suitable for the assembly of pulleys, plate wheels, gears, etc.

Unified DIN 705 locking rings and Locking rings with ledge "CFU - CFB"

- According to DIN 705;

- Available with ledge;

- In stainless steel, available on stock.

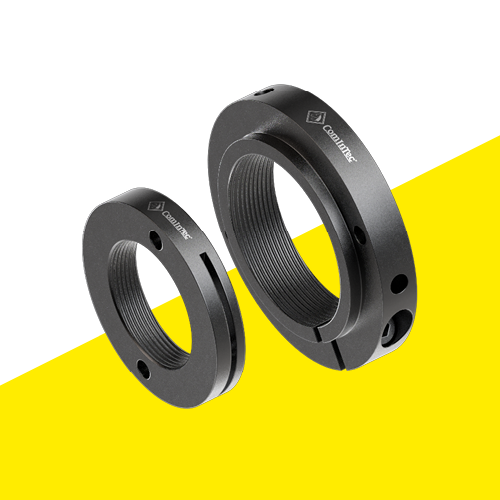

Locking ring with radial locking and one or two sections "CFBR - CFBR-2"

- 1 cut radial locking;

- 2 cuts radial locking with incision reference to assembly;

- Standard burnishing treatment.

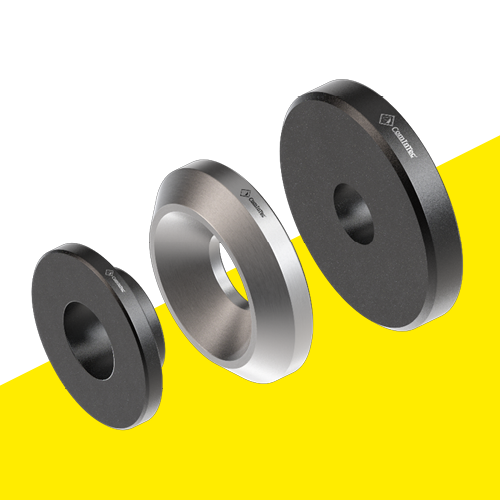

Turned washer large thickness, conical turned and for rod ends "RLGS - RTC - RTS"

- Fully turned;

- Barr-free in the edges;

- Standard phosphating treatment.

Radial and axial locking nut "GR - GA"

- Fully turned;

- Barr-free in the edges;

- Standard phosphating treatment.