Torque limiter for gearboxes

Up to 2,800 Nm of torque and 65 mm bore diameters.

A safety coupling designed to be mounted between the motor and gearbox using a B5 spacer flange. Available in sliding (DF) and disengage (DSS/F/SG-PR-V) versions. Placing the limiter on the high-speed side (between the motor and gearbox) allows for a significantly smaller device size and reduced costs compared to output-side solutions.

- Steel safety coupling with a fully machined aluminum spacer;

- Standard anti-corrosion phosphating treatment on the torque limiter;

- Compact solution;

- Designed for IEC motors and gearboxes;

- Protection in both directions of rotation;

- Instant disengagement upon reaching the set torque;

- Simple calibration system using the “H” dimension for immediate device setup.

- Supplied pre-configured and ready to use;

- Different friction ring performance options available for slip models;

- ATEX compliant backlash-free ball model with free rotation;

- Specific surface treatments available for corrosion resistance.

- Conveyor belts;

- Packing machines;

- Packaging machines;

- Handling and positioning systems.

- Superior simplicity and sensitivity compared to integrated gearbox solutions;

- Protects the gearmotor from accidental collisions or impacts against mechanical stops;

- Reduces downtime in the event of an overload;

- Absorbs starting torque peaks without disconnecting the transmission.

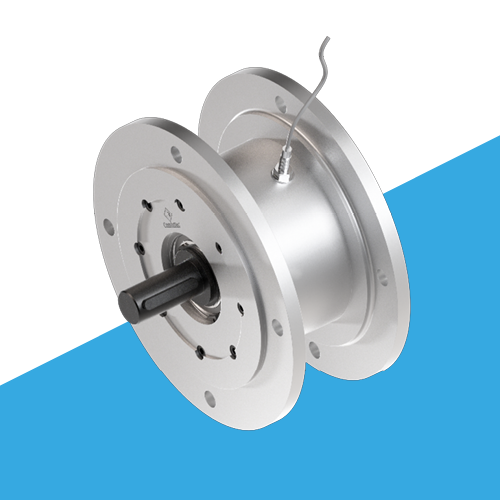

Balls solution, torsional backlash free "DSS/F/SG/PR-V"

- Backlash-free ball transmission system; maintenance-free;

- Instant disengagement between driving and driven parts in the event of overload;

- Available with single-point (360° synchronous) engagement;

- Complete solution including aluminum connecting flanges for IEC B5 motors;

- Integrated inductive sensor for overload monitoring;

- Torque range: 2 – 720 Nm; Max. bore/shaft: ø48 mm.

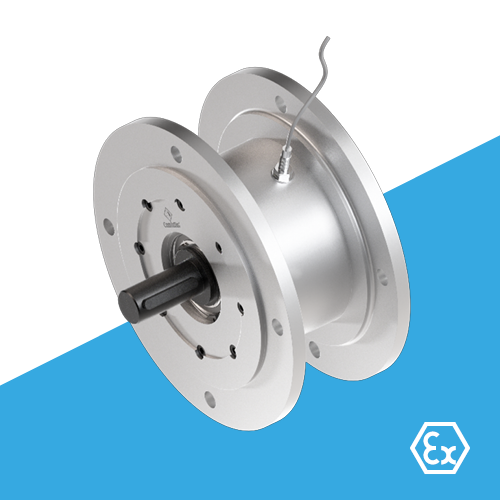

Balls solution, free rotation torsional backlash free model "DSS/SG/RF/PR-V"

- Backlash-free ball transmission with free rotation; maintenance-free;

- Instant disengagement between driving and driven parts in the event of overload;

- ATEX conformity: II 2 G Ex II B T5 Gb -15°≤Ta≤+80°C;

- Complete solution with aluminum connecting flanges for IEC B5 motors;

- Integrated inductive sensor for overload monitoring;

- Torque range: 2 – 1,300 Nm; Max. bore/shaft: ø65 mm.

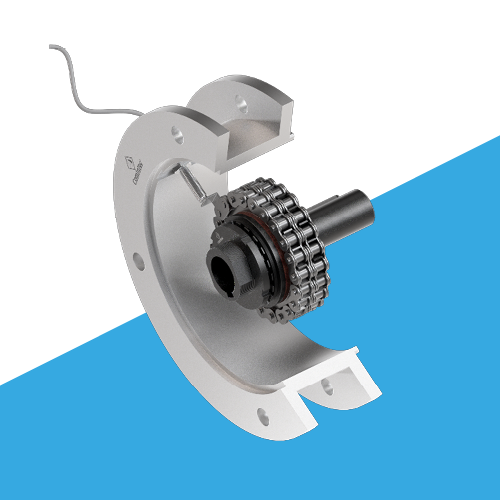

Friction model version with chain coupling for gearboxes "DF/TAC/PR-V"

- Compact and economical solution;

- Slipping of the driving part allows torque limitation without physically disconnecting the transmission;

- Silent, vibration-free intervention;

- Complete solution with aluminum connecting flanges for IEC B5 motors;

- Option to integrate an inductive sensor for overload monitoring (DF/TAC/PR-V/S);

- Torque range: 1 – 1,200 Nm; Max. bore/shaft: ø55 mm.

Friction model version "DF/PR" and "DF/TAC/PR"

- Possibility of friction rings with different performance characteristics for specific needs;

- Specifically designed for installation on hollow output shaft gearboxes;

- Available complete with fully turned and fitted transmission components;

- Available with statically balanced radial nut (…/GR);

- Model for gearboxes with a chain coupling, suitable for coaxial shaft connections (DF/TAC/PR);

- Torque range: 1 – 2,600 Nm; Max. shaft: ø55 mm; Max. bore: ø65 mm.

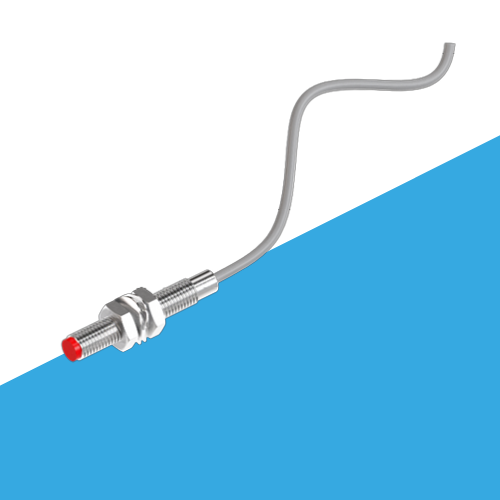

Proximity sensor "PRX"

- Standard version: Stainless steel housing with protection rating IP67 (DIN 40050);

- Supply voltage: 7 ÷ 30 VDC;

- Frequency: 4 KHz;

- Current consumption: ≤ 10 mA (Max 200mA);

- Output: NPN (N.O.-N.C.) – PNP (N.O.-N.C.);

- Operating distance: Max 1.5 mm;

- Cable length: 2 m (3×0.2);

- Operating temperature range: -25°C to +70°C;

- ATEX model available (PR-EX).