Variable speed pulleys and motor slide bases

Expandable-disc pulleys (divided into two main families) represent the simplest and most cost-effective solution for rapidly and continuously changing the rotation speed of two shafts without stopping the transmission.

- High reliability;

- Wide product selection;

- Easy installation;

- High-precision manufacturing;

- Competitive pricing without compromising quality;

- “Made in Italy” certified quality.

- Variable Center Distance: Consists of two discs sliding symmetrically on a hub. It transmits motion to a “fixed” driven pulley with speed ratios up to 1:3.5, achieved by varying the distance between the centers of the two pulleys.;

- Fixed Center Distance: Consists of a pair of pulleys, both featuring a single movable disc. This allows for speed variation with a ratio of up to 1:12.3, adjusted via a handwheel on the driving pulley..

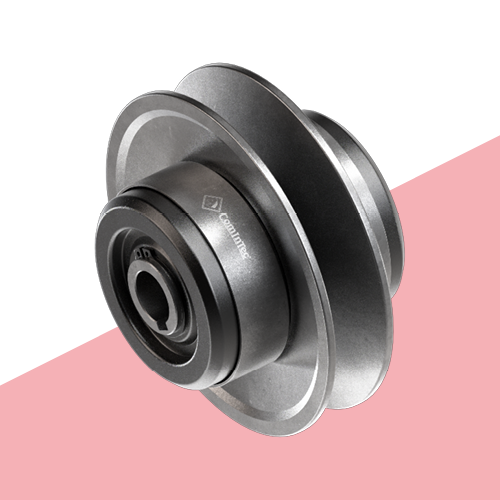

Model with self-lubricating round hub and galvanized plates "VAR.D.E.A.C./MTZ"

- Discs with anticorrosive galvanizing treatment;

- Self-lubricating round hub, maintenance-free;

- Very silent operation;

- Fully protected helical springs, suitable for dusty environments;

- Suitable for high power applications;

- Max ratio: 1:3.4 – Max power: 18.5 kW.

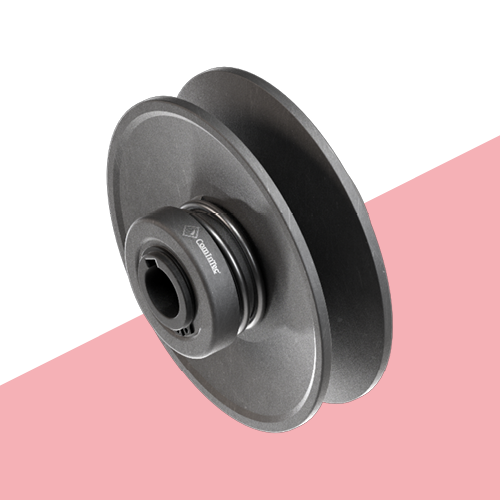

Model with round hub end helical springs "VAR.D.E.A.C./MTE"

- Discs with phosphating treatment;

- Self-lubricating round hub, maintenance-free;

- Partially covered helical springs;

- Compact model;

- Economical model;

- Max ratio: 1:3.5 – Max power: 4 kW.

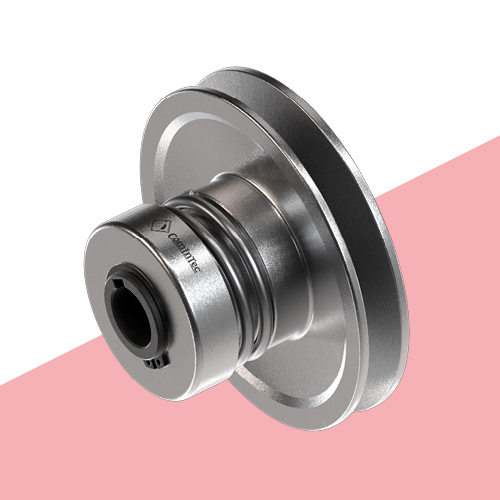

Model with mono-expandable disc, compact series "VAR.D.E.A.C./CAMPACT"

- Mono-expandable pulley with helical spring;

- Discs with anticorrosive galvanizing treatment;

- Self-lubricating round hub, maintenance-free;

- Suitable for standard small section V-belts (max 17×11 mm);

- Compact model;

- Max ratio: 1:2.5 – Max power: 1.5 kW.

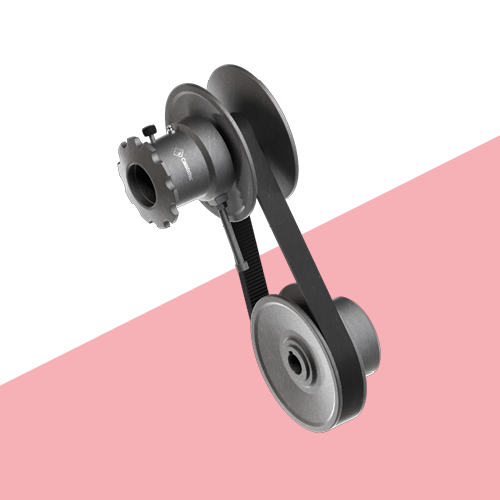

Model with round hub end helical springs "VAR.D.E.A.C./TE/IF"

- Self-lubricating round hub, maintenance-free;

- Pair of mono-expandable pulleys with phosphated discs;

- Disc adjustment via handwheel;

- Max variation ratio: 1:12.3;

- Self-aligning during speed adjustment;

- Max ratio: 1:12.3 – Max power: 18.5 kW.

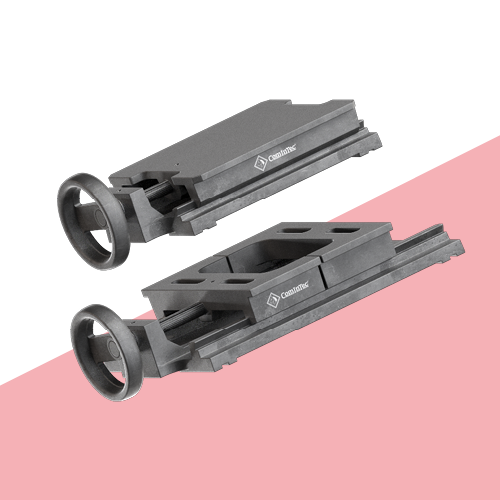

Die casting iron motor slide base "PMG"

- Manufactured from cast iron;

- Maximum rigidity and stability;

- Available with single or double sliding plate;

- Equipped with a handwheel for easy adjustment;

- Double sliding plate model is pre-drilled for motor assembly;

- Available for IEC motors 56A – 180L.

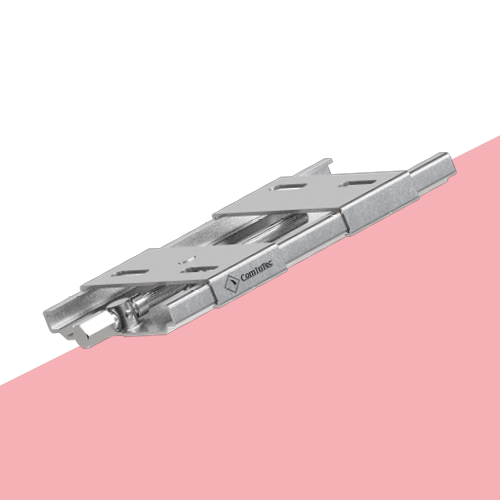

Sheet steel motor slide base "PML"

- Manufactured from galvanized sheet steel;

- Galvanizing treatment applied after bending and machining to prevent oxidation/corrosion on all elements;

- Precision alignment ensures smooth sliding and prevents deformation;

- Completely pre-drilled model for quick installation and motor assembly;

- Excellent price/performance ratio;

- Available for IEC motors 56A – 180L.